Ecostone PLUS

THE NEW HEIN ECOSTONE PLUS

More economical, efficient and powerful

due to the integrated heat recovery and thermal stone walls.

THE HEAT STAYS INSIDE

The core of the ECOSTONE PLUS is the newly designed HEIN heat recovery system:

The ground-breaking, purely physical flue gas recirculation system enables the solid steel pipes and thermal brick walls to extract additional heat from the flue gases and store it temporarily in the heat recovery system. The residual heat is not discarded but remains where it belongs: in the oven.

The heat recovery systems available on the market all follow the same strategy: hot combustion gases (300°C and more) are cooled by water in a heat exchanger. The hot water is stored temporarily and must be consumed. Complex systems do not even succeed in combining the produced amount of hot water with the real consumption, so that either the amount of hot water is not sufficient or the hot water storage tanks are not exhausted between baking periods.

The fact is that the heat consumption of the oven is not reduced, which means that the oven itself is neither improved nor made more economical, but the heat loss is only stored temporarily in one or more water stratified storage tanks.

With the ECOSTONE PLUS heat recovery system, HEIN has managed to leave the heat where it should be: in the oven for baking the products.

The hot combustion gases are routed downstream of the heat exchanger of the oven, through the heat recovery system integrated in the oven wall. The temperature of the flue gas is reduced by an average of 150°C (when baking shot on shot), so that the temperature of the flue gas is 51°C lower than the baking temperature when entering the chimney (TÜV report no. ET 385 2011 M1)

The ECOSTONE PLUS heat recovery system allows the reduction of the temperature of the baking chamber to be slowed down after charging, steaming and at the end of the steaming time, and this without the burner running. The unavoidable decrease of the temperature caused by the charging process can therefore be reduced by 20°C. In addition to massive energy savings, shorter baking times, better dough development and best crust formation have only a positive influence

on your goods.

THE HEAT RECOVERY SYSTEM

The heat that escapes during loading/unloading and baking is replaced more quickly, thus slowing down the usual

temperature drop: the oven temperature drops by an average of 20°C less, which has a positive impact on baking quality.

Here, a strong heat accumulator with energy recovery system of at least 200 kg is available.

A shorter burner running time of about 5% and a lower connection value of 10% compared to a normal rack oven will

accordingly reduce energy consumption by up to 20% (read more in the brochure).

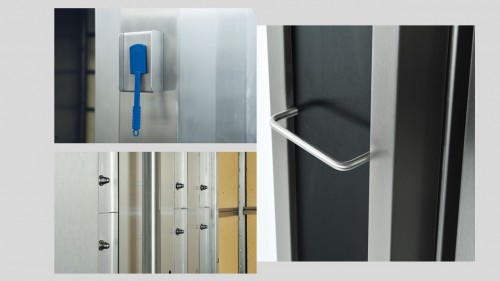

THE DESIGN

The HEIN ECOSTONE PLUS is delivered with head suspension or rotary plate as desired. It can accommodate all models of other baking trolley manufacturers. HEIN will build the oven around your existing racks if the baking trolley is available. The inclined roller track of the head suspension allows the baking trolley to be inserted without a ramp; during baking, the rack wheels have no contact with the oven base. With recessed mounting, baking without ramp is also possible with the rotary plate.

The HEIN ECOSTONE PLUS bakes your products on a rotating baking trolley (head suspension or rotary plate) in a constant air flow regulated by SOFTAIR. The SOFTAIR control allows the infinitely adjustable regulation of the air flow between 60% and 100%. These settings can be stored in the individual baking programs.

The perfectly dosed air volume will bake your finest baked goods gently and carefully. The HEIN ECOSTONE PLUS can be optionally equipped with the preserving, frequency-controlled “soft” start (SOFTSTART).

The heat recovery system integrated in the rear wall of the oven and the thermal brick walls ensure that the temperature drops less after loading/unloading, during steaming and the steaming exposure time, even though the air circulation and the burner are not running. The solid door system (HEIN lifting/lowering mechanism), which

has been tried and tested for decades, closes the baking chamber steam-tight.

Steam and heat therefore remain where they belong. The steamtight door thus also prevents discoloration above the oven door caused by steam escaping.

THE CONTROL TECHNOLOGY

The newly developed touchscreen controllers in 7” or 10” are equipped with heat-resistant electronics that can withstand temperatures of up to 60°C. The circuit boards are sealed to protect the electronic components from environmental influences and equipped with a brilliant display with a resolution of 800x480 pixels made of real glass and LED background lighting. See more in our brochure.

THE BENEFITS OF THE ECOSTONE PLUS SERIES AT GLANCE

- ALL IN ONE = Rack oven with integrated heat recovery.

- No additional craftsmen for assembly.

- No power consumption due to heat recovery as it is 100%. mechanical.

- No connection to building services / central heating - no externalheat storage.

- Self-regulating without complex control technology, monitoring or programming.

- Heat recovery completely maintenance-free.

- Recovery with every burner run (when baking shot on shot).

- Long service life identical to that of the heat exchanger.

- Energy consumption reduced by 20% (oil / gas).

- Better baking results due to the required baking temperature being reached quicker after loading.

- Additional energy savings due to shorter baking times.

- No idle times (reheating times) when baking shot on shot.

- The heat remains where it is produced and needed for baking: in the oven.