Luxrotor

HEIN LUXROTOR, rotary rack convection ovens. Available in S to XXL

Baking surfaces of 4.3 to 36.2 sqm)

The dough passes through all the horizontal parts of the baking chamber at the same level. New technologies such as SOFTAIR make it possible, among other things, to optimally regulate the speed of the baking air and the rotation speed of the suspended rack. This guarantees perfect baking quality.

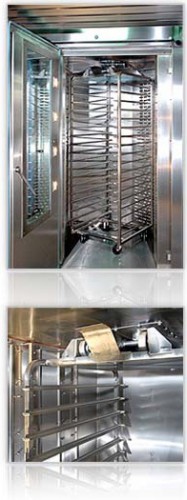

The unique door system means that the oven is totally sealed. All the parts which need to be serviced are accessible from the front, so the LUXROTOR can be built in on three sides. The extra-large, extra-powerful steam device guarantees an abundance of steam, even when the oven is being used intensively.

The front, door, body and interior of the oven are made entirely from stainless steel. The hood, also in stainless steel, with a highly efficient extractor evacuates all the steam and heat which escape when the door is opened. The LUXROTOR does not require an access ramp thanks to the unique automatic rack suspension system.

LUXROTOR LR-86-H (for 1 rotary rack)

A baking surface of up to 9.6 square metres on only 2.2 square metres of floor space.

That is equivalent to ± 680 rolls per batch (on 2.2 square metres !).

- 1 rack with 18 baking trays (80 x 60 cm)

- 142 cm (d) x 155 cm (l) x 230 cm (h)

LUXROTOR LR-812-H (for 2 rotary racks)

A baking surface of up to 18.1 square metres on only 4.2 square metres of floor space.

That is equivalent to ± 1,280 rolls per batch (on 4.2 square metres !).

- 2 racks with 20 baking trays (78 x 58 cm)

- 197 cm (d) x 215 cm (l) x 273 cm (h)

As compared to installing two single rotary ovens alongside one another, you gain ± 1 m in width, a cost reduction of ± 25% and energy savings of ± 20%.

LUXROTOR LR-1612-H (for 4 rotary racks)

A baking surface of up to 36.2 square metres on only 6.6 square metres of floor space.

That is equivalent to ± 2,560 rolls per batch (on 6.6 square metres !).

- 4 racks with 20 baking trays (78 x 58 cm)

- 244 cm (d) x 271 cm (l) x 273 cm (h)

As compared to installing four single rotary ovens alongside one another, you gain ± 3.5 m in width, a cost reduction of ± 40% and energy savings of ± 35%.

TOUCHMATIC CONTROL

With the TOUCHMATIC control for the LUXROTOR range, HEIN demonstrates once again its capacity for innovation.

This multifunction control makes for easy, structured operation. The settings for the baking process include new technologies such as SOFTAIR, which makes it possible, among other things, to optimally regulate the speed of the baking air and the rotation speed of the suspended rack.

At the SÜDBACK trade fair in Stuttgart, HEIN was awarded the SÜDBACK TROPHY for technological innovation for the TOUCHMATIC system.with a HEIN SPIDER fully or semi-automatic feed system.

The HOOD

The extra large, extra powerful hood can be fitted with a large remote display showing the baking temperature and remaining baking time.

This means that this information can be checked from a distance.

THE CLOSING SYSTEM

The unique one piece closing system means that the baking chamber is totally sealed. Steam and heat stay where they are needed – in the oven – without the product drying out.

The sealed door makes it possible to prevent the formation of dark marks (due to steam) on the front of the oven.

The oven remains clean for years. A longer life is thus assured

THE CONSTRUCTION

The HEIN LUXROTOR bakes products using a rack that turns in a continuous flow of air. Hot air is injected through the adjustable opening and is distributed uniformly throughout the baking chamber. As a result, the load is subjected to the same heat conditions, regardless of the deck on which the rack is located. This means that the entire load is cooked in a uniform manner.

When the rack is placed into the baking chamber, it is automatically lifted onto the suspension system’s inclined running rail. This makes a loading ramp unnecessary. The back of the oven is completely clear and flat.

The baking chamber is easy and quick to clean - so it is also economical. Using an adaptern the HEIN LUXROTOR can be equipped with practically any other brand of oven rack.

ROTARY PLATE

Our rotary ovens can be made with a special rotary plate to use racks of all brands.

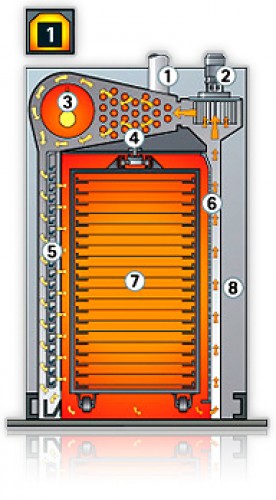

The operating principle of the LUXROTOR model with 1 rack

1. Exhaust gas duct

2. Convection turbine

3. Burner

4. Rotary mechanism

5. Extra-powerful steam devices

6. Suction wall

7. Suspended rotary rack

8. Insulation

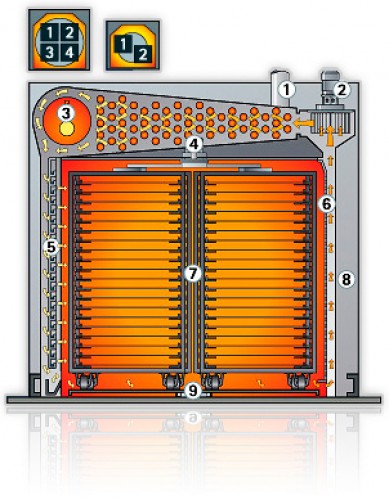

The operating principle of the LUXROTOR model with 2 or 4 racks

1. Exhaust gas duct

2. Convection turbine

3. Burner

4. Rotary mechanism

5. Extra-powerful steam devices

6. Suction wall

7. Suspended rotary rack

8. Insulation

9. Turning device

Advantages

- Steam and performance for successive oven loads

- Maximised baking surface for minimal occupied space, compact and robust

- Reduced investment and energy consumption

- Reduction of connection costs (just a chimney, a steam extractor and a single electric connection)

- Very high increase in productivity