Thermo

Is the THERMO the ideal solution for your needs?

The THERMO oven, heated by thermal oil, combines the advantages of rack baking (e.g., HEIN ECOSTONE PLUS) with the gentle radiant heat baking of an annular tube oven (e.g., HEIN UNIVERSAL PLUS).

Rack baking significantly simplifies the baker’s workflow and provides high production versatility (small and large products, sandwich bread, pastries, etc.). The number of decks (7 to 10) is determined based on the specific needs of your production (standard or large-volume products).

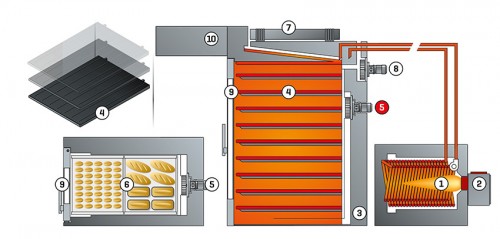

The system

The thermal oil heating system is comparable to a central heating system.

In a heating generator (1), special oil circulating in heating plates is heated using a burner or electric resistances (2) (primary circuit). This thermal oil is a highly fluid mineral oil that can be heated to over 320°C. Thanks to the high heat capacity of thermal oil, the oven temperature remains stable and is barely affected by door openings or product loading.

Due to the minimal difference between the actual baking temperature and the thermal oil temperature, products in the oven are not at risk of burning, even with partial or prolonged baking. This ensures a perfectly uniform bake.

The heating plates (4) provide particularly gentle and moderate radiant heat to the baking trays and grids. A constant baking atmosphere is maintained within the oven.

A forced air circulation system using an extraction and impulse turbine (5) enables additional programmable convection baking to promote the formation of a thicker crust. This TURBO-CONVECTION is also highly recommended for baking pre-baked bread and moulded bread. Your products will always benefit from

optimal baking conditions.

The boiler does not need to be installed near the oven, allowing for more workspace and improving working

conditions (reduced noise and heat emissions).

The boiler’s power can be adjusted to allow multiple ovens to be connected simultaneously. In the event of future baking capacity expansion (additional oven purchase), the investment will be significantly reduced.

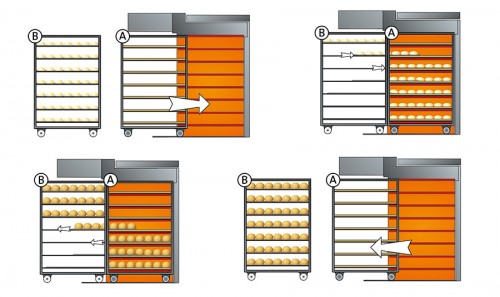

Baking on stone soles with a belt loader and unloader

If your customers increasingly demand stone-baked bread and baguettes but you lack the space for an additional deck oven, we have the ideal solution!

The mobile stone baking system for the Thermo enables baking on stone with a capacity of 140 to 240 loaves.

This means you have two ovens in one. Simple and efficient.

1. Preheat the rack equipped with stone soles (A) in the THERMO (approximately 30 minutes).

2. The dough pieces, placed on a combi-rack with belt loaders/unloaders (B), are deposited onto the stone

soles.

3. After baking, the combi-rack with belt loaders/unloaders (B) allows for quick unloading of the baked

products.

4. To switch to baking with flat plate racks, simply remove the stone sole rack (A). Production continues without

downtime.

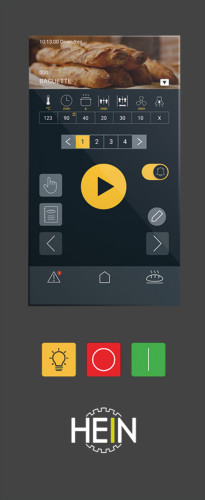

CONTROL SYSTEM

The THERMO oven’s touchscreen allows programming and controlling temperature, baking times, steam injection, TURBO-CONVECTION activation, etc.

• Can store up to 500 different programs, with up to 7 steps or instructions per baking program.

• Easy to use, minimizing errors due to incorrect operation.

SUMMARY

◉ Heating System: The mineral thermal oil, heated inside the boiler or via electric resistances, circulates through the radiators on each deck, returning to the heat generator. The patented oil circulation system ensures absolute baking

consistency. Thanks to the high calorific capacity of thermal oil, the oven temperature remains stable and does not fluctuate when the door is opened or when loading products.

◉ Monoblock design (oven and boiler). Maximum baking surface relative to floor space.

◉ Steam Production: Steam is generated in a steam generator located at the top of the oven, heated via the same circuit as the thermal oil. The amount of steam is automatically regulated via the control panel. Thanks to its unique design, a uniform distribution of a predefined quantity of saturated steam is always ensured. Dough pieces are perfectly enveloped in steam at the start of baking.

◉ Baking Chamber: Completely sealed and entirely made of stainless steel.

◉ Radiators: Made of high-strength steel. The exclusive design allows up to 10 baking decks while maintaining the same height as systems limited to a maximum of 8 levels. This significantly increases the baking surface.

◉ Mineral Thermal Oil: Never needs to be changed or filtered.

◉ Door:

• Large viewing window for an excellent view of the products inside the oven.

• IR-treated double glazing significantly reduces heat radiation.

• New Integrated Lighting System: Located in the door for easy maintenance.

◉ Oversized Hood with Powerful Extraction System: Ensures perfect steam evacuation when the door is opened. It is directly connected to the oven’s exhaust chimney.

◉ TURBO-CONVECTION (Dynamic Baking Atmosphere in Addition to Gentle Radiant Heat): Highly recommended for producing pre-baked bread and molded bread. This system ensures forced air circulation in the baking chamber via a suction and impulse turbine. The forced air enables additional convection baking, programmable during the final minutes of the baking cycle.

◉ Controls: Touchscreen for easy operation.

◉ Minimal Maintenance: The oven contains no moving parts inside.<

◉ Heating Options: Gas, oil, electricity or hybrid (electricity combined with gas or oil).