Electro

ELECTRO, AN OVEN HEATED BY ELECTRIC ELEMENTS

(baking surfaces of 3 – 23 sqm)

3, 4, 5, or 6 completely sealed decks which can be regulated independently (individual adjustment of the base plate and vault). Each deck has an extra-powerful steam device. The patented oven front and doors are built of 2.5 mm stainless steel. Each deck is fitted with an overpressure valve which does not require any maintenance.

A 100 cm deep stainless steel extractor hood with an extra-powerful extractor fan absorbs all the steam and heat when the doors are opened.

ELECTRO ELECTRIC OVENS: Clean energy, state of the art technology, easy handling.

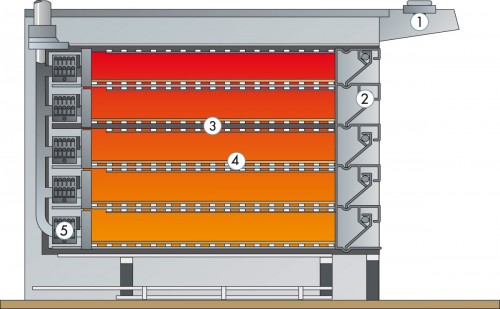

The operating principle of the ELECTRO

1. Extractor hood

2. Deck doors (patented tilting mechanism)

3. Thermal insulation between the decks

4. 22 mm thick cast thermal stone plates

5. Oversized steam unit

THE STANDARD CONTROL S1

The typical control for an electrically heated deck oven. The large digital displays enable practical

handling of the decks and reading of the set and actual temperatures as well as all data displayed by

the control.

• Controls the steaming duration and automatic opening and closing of the steaming flaps (accessory).

• It enables automatic monitoring and control of the baking process, the baking time as well as, of course, the top and bottom heat.

• The night start as well as the hood after-run time are among the basic functions of the S1 control

The S1 control helps you to save energy.

• If a deck is not used for a freely programmable period of time (no baking programme started), the control system lowers the baking temperature to a freely definable temperature

THE NEW K1 CONTROL (OPTION)

- 7” colour touch control (easy operation with clearly arranged display).

- Baking with approx. 100 baking programmes and adjustable favourites (own customer pictures possible).

- Programmable weekly timer (automatic oven start, 2 times per day can be set).

- Eco button (the oven can be temporarily set to a reduced temperature).

- Master / slave function (the master control controls the hood fan and baking programmes can be copied to individual decks).

- Intelligent energy management adjustable across all decks (a defined total power level is not exceeded with reduced power).

- Optional cloud access of the control system via internet possible (update service for HEIN, overview of oven data with PC, tablet and smartphone)

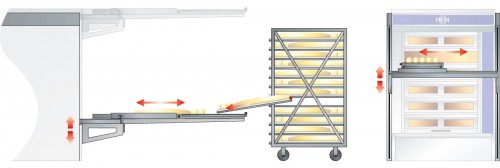

OPTION: THE NEW HEIN LIFTMASTER

LOADING SYSTEM INTEGRATED ON THE OVEN

Loading and unloading in no time at all with the help of the manual loader

Thanks to the newly developed HEIN LIFTMASTER , you no longer need to bother with large puller units.

Place your dough pieces on the LIFTMASTER with the help of the handy puller unit . To load, simply lift the LIFTMASTER to the desired deck with one hand and load. Unloading is just as easy with the LIFTMASTER

After loading, between baking or after work, the parking position of the LIFTMASTER

guarantees headroom and free access to the oven .

Advantages

- Baking chambers independent from each other in terms of temperature and steam.

- Separate heat command at the top and bottom of each baking chamber.

- Great flexibility for all your products.

- Each baking chamber has its own extra-powerful steam device that can be heated separately (making significant energy conservation possible).

- Every deck is equipped with a separate steamextractor.

- Basic heat particularly adapted thanks to massive plates and a totally homogeneous heat transfer (formation of very fine bread crust).

- Easy and intuitive handling of the oven.

- Enhanced production safety and capacity to reproduce your quality standards.

- The HEIN ELECTRO can be fit flush on three sides (option).